MU 2

Create something new

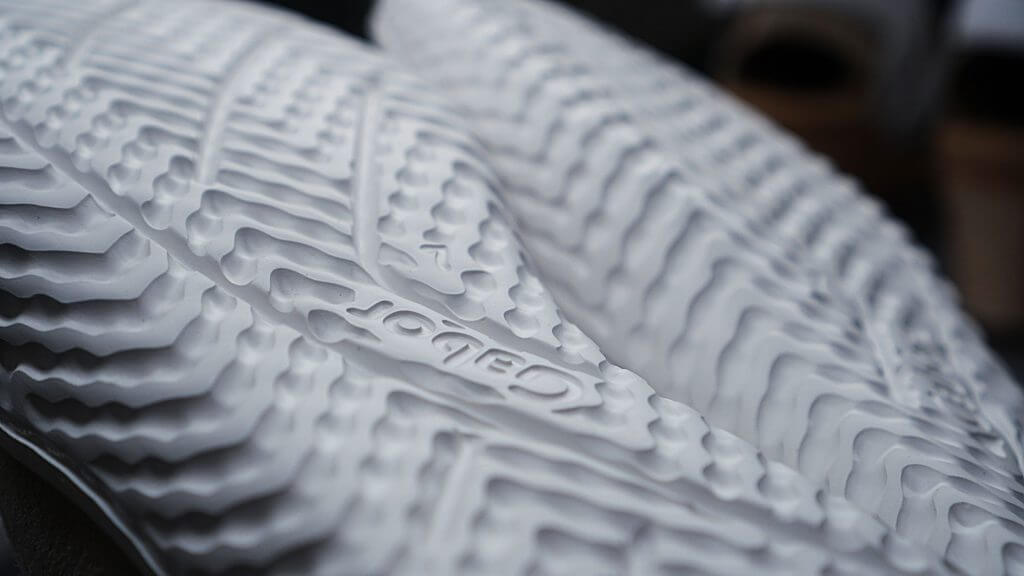

We love to innovate in MU2. It’s equipped with the latest technology – like no-sew, TPU welting, computerized stitching machines, and advanced printing machines.

We love to innovate in MU2. It’s equipped with the latest technology – like no-sew, TPU welting, computerized stitching machines, and advanced printing machines.

MU 2

Create something new

We love to innovate in MU2. It’s equipped with the latest technology – like no-sew, TPU welting, computerized stitching machines, and advanced printing machines.

We love to innovate in MU2. It’s equipped with the latest technology – like no-sew, TPU welting, computerized stitching machines, and advanced printing machines.